Sharpening Knives, Scissors and Tools

Before Sharpening, Flatten the Back of Chisels and Plane Blades

It’s impossible to get a sharp edge on a chisel or plane if the back of the blade isn’t flat. If you’re using glass and sandpaper, press the back side of the blade against the sandpaper and move the blade back and forth, being careful to hold it perfectly flat. Sand the back of each blade until it’s uniformly shiny along the cutting edge. Do this with each grit as you move through the progression from coarse to fine. Use the same technique with natural or diamond sharpening stones.

Use a Handheld Sharpener On Kitchen Knives

Most of the time you don’t need a power tool or an expensive knife-sharpening system to keep a workable edge on your kitchen knives. Regular use of a handheld sharpener is fine. This Wusthof sharpener costs $20 and works great. Other brands may work equally well, but we haven’t tried them. This sharpener has carbide steel rods to shape the blade, and diamond rods to finish the edge. Follow the instructions to quickly sharpen kitchen knives that have standard beveled edges. You’ll have to use another sharpening tool if your knives have unusual or asymmetrical angles.

Sharpen Serrated Knives With a Diamond Sharpening Steel

When using a diamond steel to sharpen a serrated knife, the curve of the steel has to fit the scallops on the knife. Take your knife to a cookware store and find a diamond-coated steel (about $30) that matches the scallop size on your knife. If you’re shopping online, you can find the diameter you need by holding drill bits against the scallops. Then use this dimension to order the right diameter sharpener. Another option is to buy a tapered, pocket-size diamond steel that accommodates a variety of different scallop sizes.

Notice that one side of the blade is flat and the other tapered. Sharpen only the tapered side. Starting at one end, sharpen each scallop with two or three strokes, matching the original angle. When you’re done, run the knife through corrugated cardboard to remove metal filings.

Touch Up a Knive With a Honing Steel

You’ve probably seen chefs on cooking shows brandishing a knife and a steel like a samurai swordsman and thought it was just for pros. But a honing steel isn’t hard to use and is perfect for restoring a sharp cutting edge to your knives. You can’t fully restore a dull blade with a steel, but you’ll be surprised how quickly you can take a slightly dulled edge to almost razor-sharpness with just a few strokes.

The safest method for using a steel is to rest the tip on a surface that’s not too slippery, like a wooden cutting board. Then pull the knife down and across, alternating sides. Keep the knife at about a 25-degree angle so you’re just tuning up the edge. The steel doesn’t actually sharpen. It simply straightens out the wavy edge so the knife slices through material better. Eventually you’ll have to resharpen the knife, but for between-sharpening tune-ups, you can’t beat a steel. You can buy a steel wherever good knives are sold.

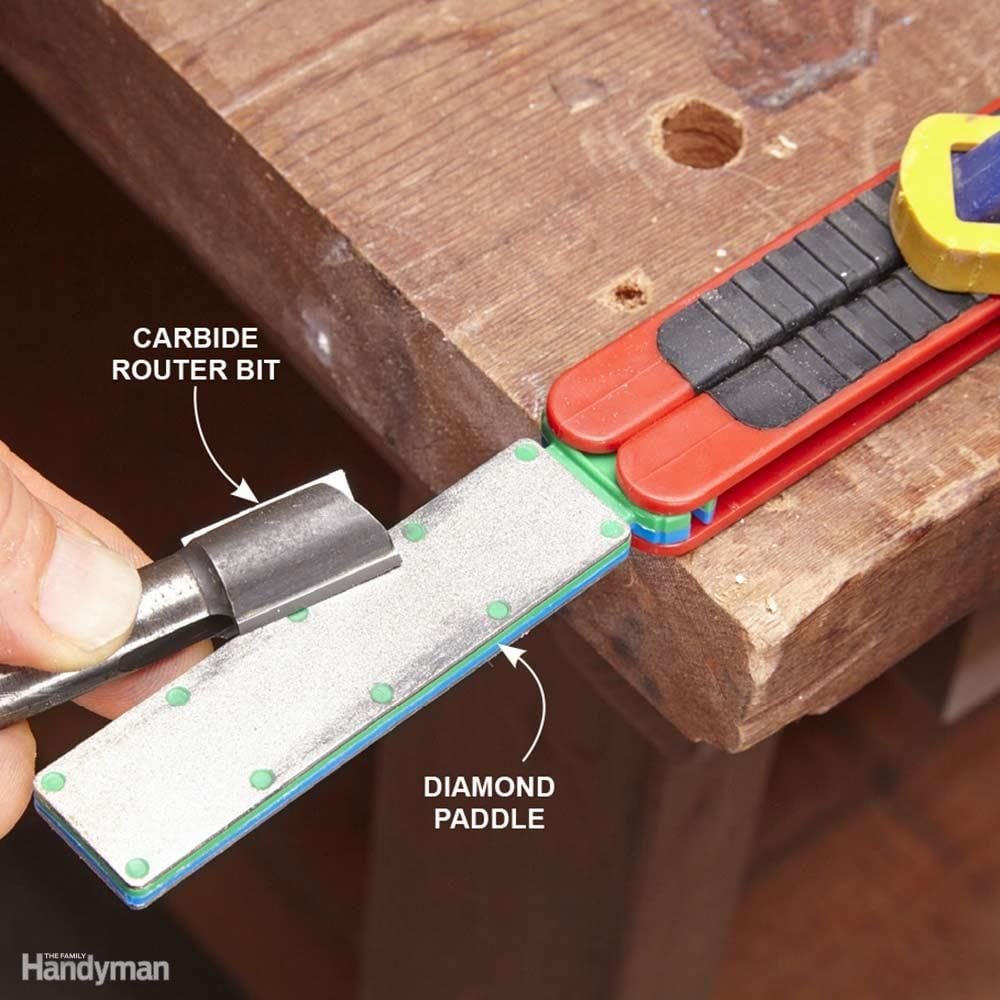

Tune Up Carbide Router Bits With a Diamond Paddle

Chipped or severely dulled carbide router bits require professional sharpening, but you can restore a slightly dulled edge with a diamond paddle. The one shown is available online and at sporting goods and woodworking stores.

To avoid changing the cutting profile of the bit, sharpen the back of the cutters only. A handy method is to clamp the diamond paddle to your workbench and move the bit back and forth over the diamond-impregnated surface. Start with the coarser-grit side of the paddle. Then switch to the fine side. The sharpened carbide should have a consistent shiny band along the cutting edge.

Sharpen Hatchets and Axes With a File

You don’t need a power tool to sharpen hatchets or axes—all you need is a sharp mill bastard file with a handle. Buy a good-quality file, and pick up a file brush while you’re at it. Use the file brush to clean the metal filings from the file’s teeth to keep it cutting well.

Clamp the hatchet, then file the edges, following the original angle. The file cuts only on the push stroke, so don’t go back and forth with a sawing motion. Start your stroke on one end of the blade and push the file up and across, applying a little pressure. Make three or four passes on one side, then do the same on the other side. Keep the number of passes equal for both sides. File until the edge is uniformly sharp. Look directly at the sharp edge with a strong overhead light. Dull spots will show up as bright reflections.

File hatchets or axes used for cutting or felling wood at about a 25- to 30-degree angle on each side. Splitting axes work better with a blunter angle, so for them, increase the angle to about 35 to 40 degrees. Filing will get your hatchet or ax blade back in shape, but if you want it really sharp, you’ll have to follow up with a stone or diamond hone.

How To Keep Your Spade Bits Sharp

If you grab a spade bit instead of an expensive Forstner bit when rough material needs drilling, this abuse will take a toll. Luckily, a spade bit doesn’t have to be sharpened with precision to work better. A few strokes along the bottom with a file and you’re back in business.

Clamp the bit in a vise and file the cutting edges, making sure to maintain the existing angle. A tapered triangular file works well for many sizes of spade bit.

New Life for Old Drill Bits

If you’ve ever tried to sharpen a drill bit on a grinder, you know what a hit-and-miss proposition it is. It’s hard to maintain the correct angle, keep the chisel point centered and avoid burning the bit.

Drill Doctor offers several versions of a special tool that makes drill-bit sharpening almost foolproof. The least expensive tool (the Drill Doctor DD350X Drill Bit Sharpener is available from amazon.com) is perfect for the home shop. You simply follow the instructions for chucking the drill bit into the tool and rotate it on the grinding wheel to sharpen

A 1-in. Belt Sander is a Versatile Sharpening Tool

Foolproof Chisel and Plane Sharpening

Sharpen Your Scissors

Sharpening scissors with a sharpening stone is tough work, but this sharpener makes the whole process nearly foolproof. It’ll sharpen left-handed scissors in one side and right-handed in the other. It has a ceramic bar that floats between the blades and automatically sets itself to the correct angle as you gently squeeze the scissors and pull or push it through the opening. Don’t push hard; just pretend you’re lightly cutting a piece of paper and maintain consistent pressure. A few passes and your scissors should be sharp.

Sharpen Your Shovel

Your shovel will slice through dirt and roots easier if it has a sharp edge. If the point of your shovel is ragged with dents or chips, start by smoothing it with a metal grinding disc in an angle grinder. Keep the grinder moving to avoid overheating the metal edge. Then switch to a mill bastard file to file a bevel. Hold the file at a 70-degree angle to the back of the shovel. Apply pressure while pushing the file (files cut on the forward stroke only). Lift the file to return for the next stroke. You don’t want a knifelike edge. Just bevel the top edge at a 70-degree angle to the back. That’s pretty blunt compared with the 25- or 30-degree angle used for knife sharpening.

Restore a Lawn Mower Blade

Outfitted with a grinding wheel, an angle grinder is a great tool for restoring edges on lawn mower blades. If you need a sharper edge than the grinder leaves, follow up with a mill bastard file. To sharpen a lawn mower blade, orient the grinder so that the wheel spins from the body of the blade toward the edge (refer to the arrow on the body of the grinder to determine which direction the wheel spins).

Finally, with the grinder off, rest the grinding wheel against the blade and adjust the angle of the grinder to match the blade’s bevel. This is the position you’ll want to maintain as you grind the edge. Lift the grinder from the edge, switch it on and let it come to speed before moving it into the blade. Stroke the grinder across the work in the direction of the handle rather than grinding back and forth. Then lift it off and repeat, concentrating on holding the grinder at a consistent angle throughout the stroke. It’s easy to overheat a metal blade with a grinder. Overheated metal turns a bluish black or straw color and won’t stay sharp for long.To avoid overheating, apply only light pressure and keep the grinder moving. Also keep a bucket of water and sponge or rag handy and drench the metal frequently to keep it cool.